What Exactly Is Gilding?

To many of the uninitiated, intrigued by the beauty of gold leaf, one of the first questions I hear concerning gilding is “what makes it stick?”. It’s actually a long answer, depending on the method of gilding, historical reference, and personal choice.

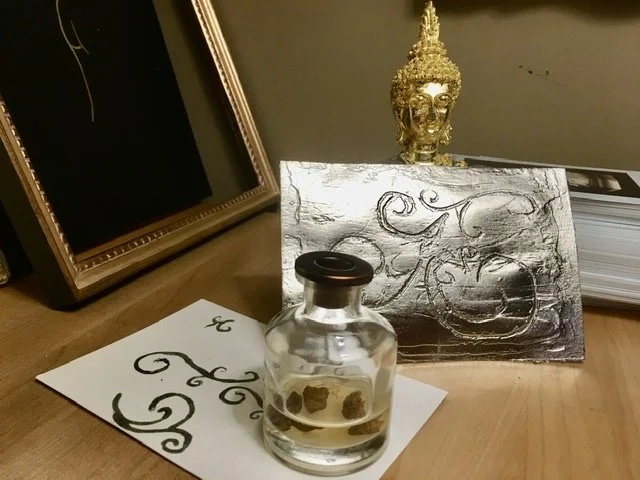

Gilding, which is the application of a metal leaf to another surface is comprised of three main methods: Water Gilding, Mordant Gilding, and Glass Gilding/Verre Églomisé. Water Gilding is used primarily on wood although can also be performed on plaster, hydrocal, and a mould-making material known in the Framing and Furniture world as Compo. Mordant Gilding which includes such adhesive agents as oil size and acrylic emulsion is designed for any non-porous surface from sealed wood and glass to stone and walls. Glass Gilding can be performed on either the front or the back of glass, from mirrors and tabletops to decorative glass sculptures and gilded and painted sceneries of age-worn Grandfather Clocks.

Within these methods lie the techniques used for Byzantine, Russian, and Greek Iconography, Manuscript Illumination, 13th-18th c Florentine gilded panel paintings; the gilded architecture of Cathedrals and Domes and Palaces; the ornate picture frames of French, Italian, Flemish, and early American design; Asian temple woodcarvings, Tibetan metal work; the decorative effects of raised gesso for calligraphy or its use on frames and furniture in the form of pastiglia; the beauty of egg tempera paint over water gilded gold leaf and etched away in a method known as sgraffito; and the gesso treatments of granito. The uses of gilding throughout the centuries seems endless.

Water Gilding

Traditional water gilding generally involves rabbit skin glue and/or gelatin; glass gilding/verre églomisé uses a food grade gelatin for bright gilding or oil size for contrasting matt sections although glair - beaten egg white - can also be used as described by Ceninni in his 15th c Treatise Il libro dell’Arte for religious reliquaries which also leans matt, depending upon the strength. Oil size is a popular bonding medium in mordant gilding alongside other mordants including garlic, gum ammoniac, and contemporary acrylic emulsions. The use of these mordants extend from oil gilded interior and exterior architecture to the application of glair and gum ammoniac for manuscript illumination and bookedge gilding.

Each of these bonding mediums carry their own characteristics and purpose of use. Referred to as Size, many mordants such as oil size and acrylic emulsion (sold as water-based adhesive) are applied topically to a non-porous surface and allowed to dry to a slight tack on which the gold, silver, or other precious or non-precious metal leaf is applied. Both of these adhesive materials are considered mordant gilding. While we often hear of the popular term oil gilding, there is no separate term other than mordant gilding for gilding with acrylic emulsion and despite it being water-based it would be incorrect to refer to it as water gilding, a completely different method of gilding rooted in antiquity dating back over several thousand years.

Traditional water gilding involves a protein binder throughout the process. My method of practice begins with preparing a 10% rabbit skin glue (rsg) solution: 1 part dry granules to 9 parts distilled water. Once the granules soften overnight they are heated in a double boiler until dissolved, the mixture never surpassing 120F to avoid destruction of the enzymes which would affect the adhesive quality of the glue. The wood object to be gilded is then coated with a layer of the heated size and left to dry 24 hours, allowing the wood time to re-stabilize from the hydration.

Rabbit Skin Glue As A Binder

The Rabbit skin glue solution is also used to prepare gilder’s gesso, a combination of 10% rsg, additional water, and calcium carbonate or calcium sulphate which is applied to the sized wood. 10% rsg is also used in the preparation of the clay bole and applied over the gesso. A 10% solution of gelatin can be used for the bole instead of rsg as a matter of preference as it doesn’t require the lengthy soaking time as the rsg granuals.

The term gesso is used to convey foundation or ground. I have recently come to refer to it simply as gilder’s gesso to help differentiate it from other forms of gesso such as oil or acrylic-based. They are all referred to as gesso which can be confusing as the term is shared but the materials that are used in their manufacture are quite different. Although they each form a ground, a painter will use gesso to isolate the canvas from the effects of oil paint while a gilder will apply gesso to wood to fill the grain and in the case of water gilding, to burnish the gold to a high lustre.

During water gilding, the gold leaf is laid over the clay bole once the bole has been sufficiently hydrated with water and alcohol, reactivating the glue in the clay which bonds the leaf to the surface. The leaf is then later burnished to a beautiful brilliancy. Often the gold leaf is left matt in specific sections of the gilded object for contrast to the burnished areas.

Clay bole is obtained as either a dry cone which gilders will then grind or tumble in a ceramic tumbler known as a Ball Mill as I do with water and tumbling stones until creamy or it can be purchased pre-mixed where the clay has already been tumbled and mixed with water. This clay is then combined with a specific amount of dissolved rabbit skin glue or gelatin and applied over the gesso that has been sanded smooth. The clay provides a sympathetic color under the gold or silver leaf and aids in the effectiveness of the burnishing with an agate stone burnisher.

Gilders will often use the terms Clay Bole, Clay, or Bole interchangeably. Intriguingly, this holds true whether the clay bole is in its raw dry cone or pre-mixed state and whether or not it has been combined with the glue size. This is important to note since protein binders such as rabbit skin glue and gelatin have a short shelf life once mixed with water and should never contaminate the raw form of the clay bole which normally sits on the gilder’s shelf as it will turn the container of raw clay rancid and useless. The rabbit skin glue or gelatin should only be used to create what I call prepared bole - the solution of clay, water, and glue which is used while gilding and stored in the refrigerator when not in use.

Protein binders such as rabbit skin glue can last many months in their dry state when stored in a glass container and cabinet but breakdown fairly quickly once combined with water. Depending upon the temperature setting and condition of refrigerators, two weeks is generally a good guideline for maximum life of the prepared glue, whether in the form of the 10% water and glue size, the prepared clay bole, or the gesso. When any of these prepared materials for gilding deteriorate, which could be between 2-4 weeks in the refrigerator, the prepared glue size, clay, or gesso will develop a soft, watery texture and eventually a strong odor if left passed their prime due to the presence of the rsg or gelatin as they are both protein binders and should never be used once deteriorated since the adhesive quality will be greatly diminished.

Mordant Gilding

The method of mordant gilding with either oil size or acrylic emulsion is less time intensive than traditional water gilding although each step is very important to be done correctly to achieve an attractive gild and to avoid any stressful mishaps from wet or pooling size.

Unlike water gilding which requires a porous surface, mordant gilding requires a non-porous surface. Technically, raw wood could simply be given numerous coats of shellac to reduce the porosity on which oil size or acrylic emulsion can then be applied. Once the size dries to a tack the leaf is laid and gently compressed with either a soft pounce pad or light pressure through the thin rouged paper inside the gold leaf booklets or whatever is the gilder’s preferred method for smoothing the leaf. However, although a porous surface can be made non-porous there are other steps a gilder can take to create a more attractive gild than simply gilding over shellac-sealed wood.

I often apply six coats of gilder’s gesso to wood frames and furniture to fill the grain, sand the gesso and apply a Primer and enamel paint as an undercoat before oil gilding, or an acrylic paint as an undercoat for gilding with acrylic-emulsion, providing a nice foundation free of the presence of wood grain while the paint seals the porous gesso and offers an attractive color under the somewhat translucent gold leaf. Other preparatory treatments are often necessary for other surfaces such as metal, especially for exterior work for successful bonding and longevity.

Verre Églomisé

Gilding on glass is a method that I often refer to as Glass Gilding or by the French term Verre Églomisé, named after the 18th c French Dealer and Restorer Jean-Baptiste Glomy (1711-1786) who reintroduced the ancient Roman technique of gilding and painting on the back of glass.

As a weak size made of gelatin dissolved in water is used, some refer to this method as water gilding which I refrain from to avoid confusion with traditional water gilding. The form of gelatin used for glass gilding today comes in the form of a clear, short rectangular sheet with perforated diamond shapes for ease in measuring. Pharmaceutical capsules have also long been used and some gilders prefer these although in either case, the gelatin should be stored in a glass jar in a cool cabinet. Prepared as a water-based mordant it is best to use fresh gelatin as age can affect adhesive quality. A clear, crisp snap of the gelatin ‘diamonds’ is a good indication of fresh quality.

For the beginning gilder it is perfectly good to choose a path of specialization in a particular area of gilding, whether as a water gilder of frames or furniture, a hand-letterer on glass, a manuscript illuminator, or a restorer of gilded antiques. Whether someone chooses to specialize or to become proficient in a variety of methods and techniques it’s beneficial to acquire an overall knowledge of the various forms of gilding, their history and purpose of application. It can be helpful in a business context and in the sense of self as an artist, in one’s confidence, choices, and opportunities that may come along.

For a full listing of classes the full curriculum is currently being added to the Gilding Class Information page. ~

For those interested in studying gilding Charles Douglas Gilding Studio offers both an in-person and Online Classes including studies in Glass Gilding, Verre Églomisé, Mordant Gilding, and Traditional Water Gilding. Visit the website page Gilding Class Information for more detail or go to the Book A Gilding Class page for an up-to-date class schedule and Registration.